Have you ever wondered how your printer cartridges’ yield is calculated? Or why your cartridge is rated for 200 pages but is empty after a dozen photos or a few picture?? Here is haw that page yield is calculated for all printer brands and what affects it. Knowing this will allow you to lower your cost per page. The page yield advertised on cartidge is a bit like the Miles per gallon yield for cars. It is a standardised measure that allows you to compare different products, but it is rarely what you’ll get in real life. In both cases, this is because the measures are taken in ideal controlled conditions.

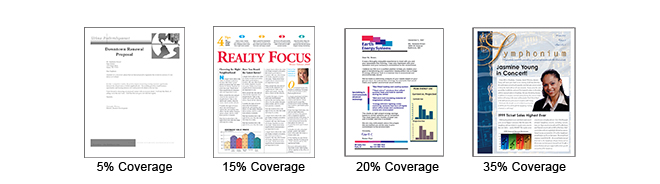

First, you must know that cartridges page yield measurement are controlled by ISO/IEC norms. It is based on a 5% page coverage average except for wide format industrial printers in which case only the volume of ink is indicated. It is thus important to know that, if your prints cover more thn 5% of the page, your yield will be lower than the advertised one. 5% coverage is about an ordinary letter on an 8.5 x 11″ sheet. You can see an example in the image below. A page full of ink is 100% coverage and will empty your cartridge 20 times faster. You can now see why photos use up your ink so quickly.

Your page yield is linked directly to your cost per page. Knowing what affects it will allow you to save money; simple as that.

Page yield for black and white printers

The black and white page shown in the opposite image. In accordance with the ISO/IEC 19752 standard, this page is printed continuously until the cartridge runs empty. This is done on 3 printers with 3 sets of cartridges on each one, for a total of 9 tests. The results are then averaged to get the final page yield.

Page yield for color printers

In accordance to ISO/IEC 19798 and 24711 norms, the 5 colored pages in the image below are printed on 3 printers until they have gone through 3 sets of cartridges each. This number is then averaged to get the page yield that will be used by the manufacturer.

These standards are the same for all manufacturers worldwide which allows objective comparisons of page yields between printers and brands. Coupled with the sales prices, you can calculate your cost per page and see which printer is the best for you.

What affects your actual page yield

Obviously, these tests are run in very carefully controlled environments. Unles you happen to need a whole bunch of these test pages, your actual yield will never be exactly the same as the advertised one. A lot of factors can influence the number of pages you get out of your cartridge. Knowing them will hopefully allow you to get the most out of them or, at the very least, understand why you’ve run out of ink.

Page coverage

The first and most important factor is your page coverage. The quantity of ink used by a print is directly proportional to the quantity and size of the stuff you print. At 10% coverage, you get half of the advertised page yield, at 25% you get one fifth and printing full pages (100% coverage) get you one twentieth of the manufacturer’s advertised yield.

Type and layout of the prints

The page’s layout also has an effect on the quantity of ink that is used. The layer of ink that is applied on the edges of the page is not the same thickness as it is in the middle of the page. Also, a print that contains only a small colered element will use more ink than an element of the same size on a page that contains more color. This is due to the fact that the color printin system’s startup cycle uses a little bit of ink and that it takes some time for the print system to reach its maximum efficiency. If you don’t need that small colored item, it is better to print in black and white. Also, black ink almost always has a lower cost per page than colored inks.

Because of these same reasons, a 5 page document will use up less ink than it would if the same 5 pages were printed seperately. Due to the ink used up by the printer start up cycle and the time it takes to reach its optimal functioning, it is recommended to regroup your prints as much as possible.

Environmental conditions

Humidity and ambient temperatures also have an effect on your cartridge’s yield. In inkjet printers, these affect the ink’s drying and its absorption by the paper. For laser printers, they affect the electromagnetic processes and the toner’s adherence to the page. An extreme level of humidity can alos have negative effects on the pare, such as warping or wrinkling. Both home and office printers and papers are designed to operate at their best in environments with a relative humidity level of about 50% and a temperature of 22C. Maintaining your rooms as close to this as possible will help maximise the duration of both your cartridges and printer.

Cartridge maintenance

Laser cartridges’ maintenance and calibration use up some ink. The same can be said of inkets alignment and printhead cleaning cycles. The best way to reduce this effect is to use your printer regularly (at least once a week is recommended for inkjet printers) and to completely turn off your printer if it’s not going to be in use for an extended period of time. It is not recommended to leave an inkjet printer unused for a long time as leftover ink may clog the printheads or the supply lines.

Duplex printing

Duplex printing improve the page yield on inkjet printers because, since the paper is already humid after the fisrt side, it more easily absorbs ink on the second pass thus reducing the quantity of ink necessary.

Réponse/Reply

Commentaires/Comments